Products

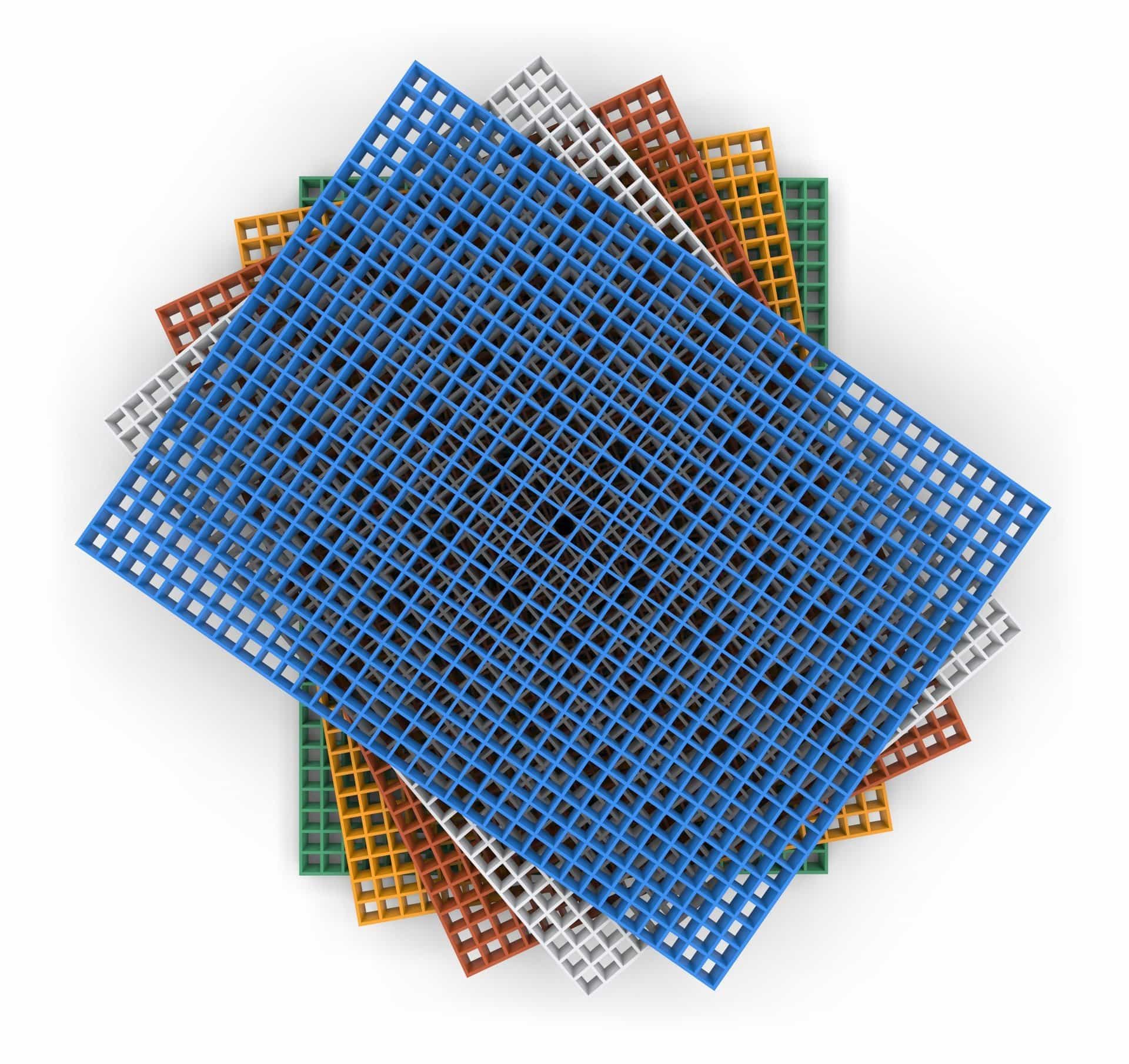

Kentec Composites Fiberglass Grating

Our products are made to the highest standards with the highest quality of raw materials. Kentec goes above and beyond the minimal standard requirements to provide you with reliable materials that will outperform and outlast the competition.

Kentec’s facilities are ISO 9001:2008 Certified.

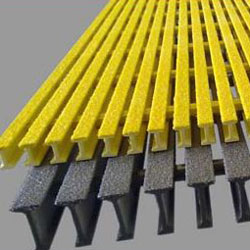

Lightweight Materials

1/4 Weight of steel grating makes installation easy and eliminates the need for heavy lifting equipment. Effortless Cutting.

Reduced Installation Costs

These problem solving products are the best choice to substitute steel and aluminum gratings in corrosive environments

Low maintenance Life Cycles

No painting, and no maintenance is required. Please keep in mind, replacement costs much to owners.

Ease of Fabrication

Unparalleled performance in most harsh chemical environments, which could not be achieved by using traditional metal grating.

Enhanced Workplace Environment

Excellent test result(BS 7976-2) guarantees sure footing on both dry and wet working conditions.

High Resin Content

Fire retardance meets standards of ASTME 84 Class 1. And what is more, extra low temperature tests witness the good performance at-196 degrees Celsius.